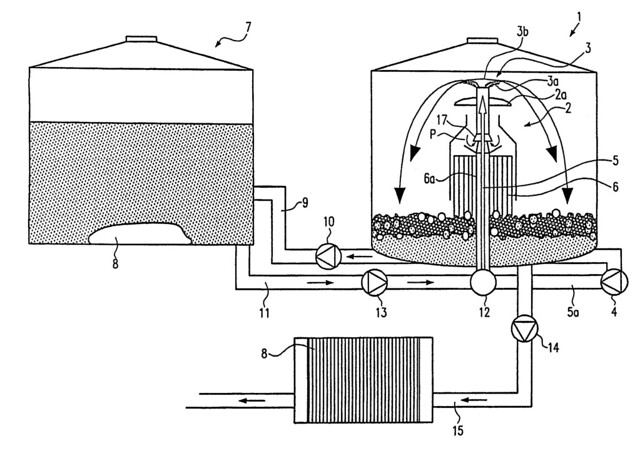

Today in 2010, US Patent 7781000 B2 was issued, an invention of Kurt Stippler and Klaus-Karl Wasmuht, assigned to Krones Ag, for their “Method For Boiling Wort.” Here’s the Abstract:

A method for boiling wort used in the production of beer the wort is boiled in a wort copper in which an inner boiler comprising a superimposed thin-film distributor is disposed. After boiling and after removal of the sludge in a whirlpool, the wort is again placed on the thin-film distributor for evaporation so that the wort copper simultaneously works as an evaporator.