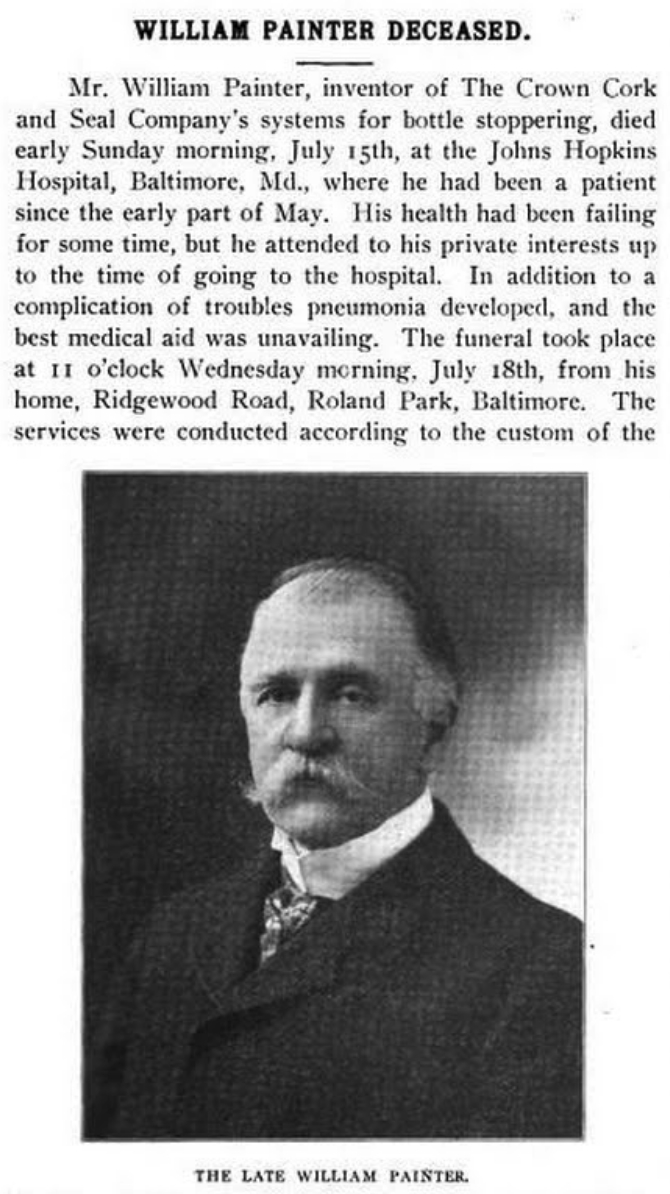

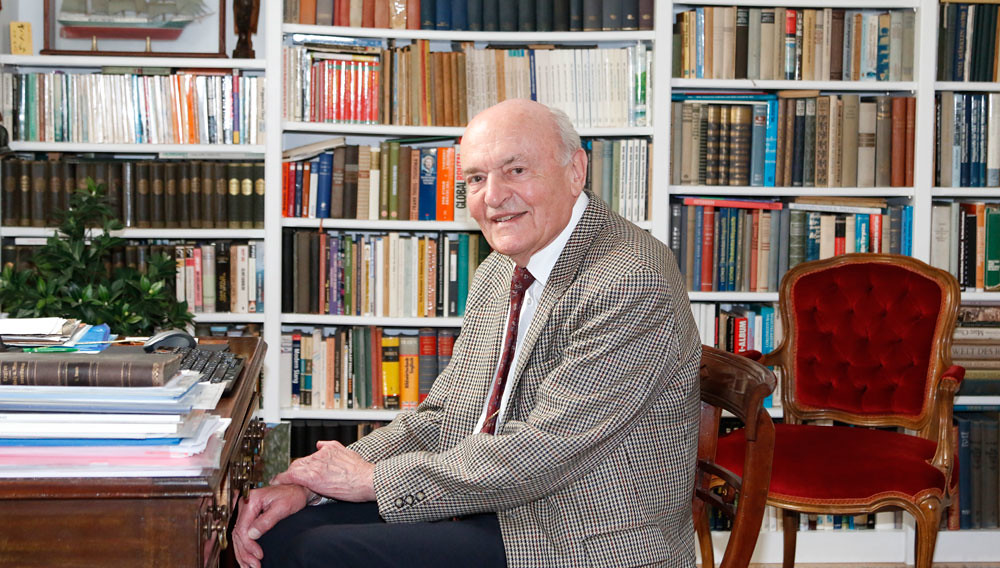

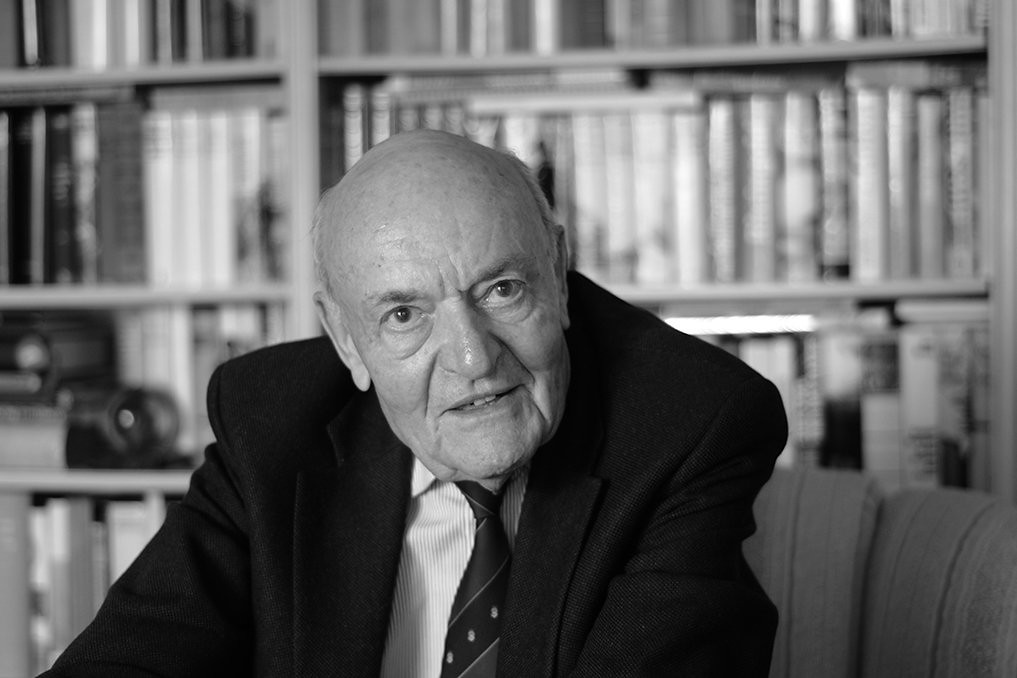

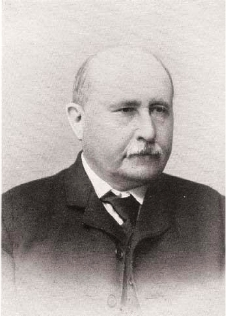

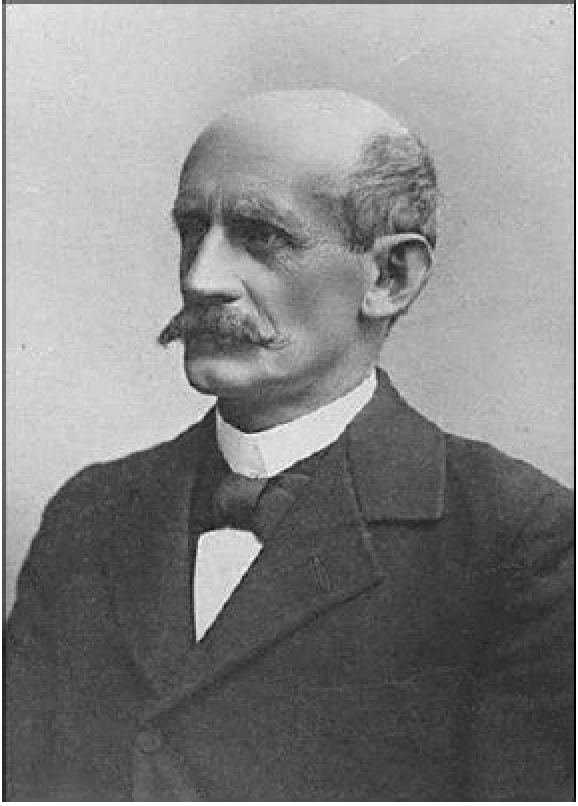

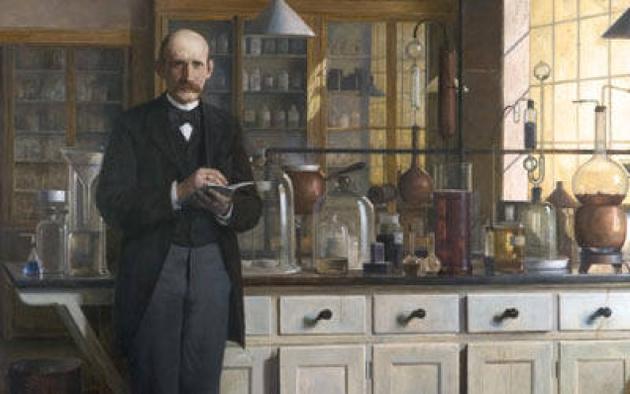

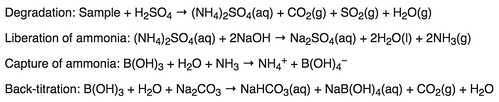

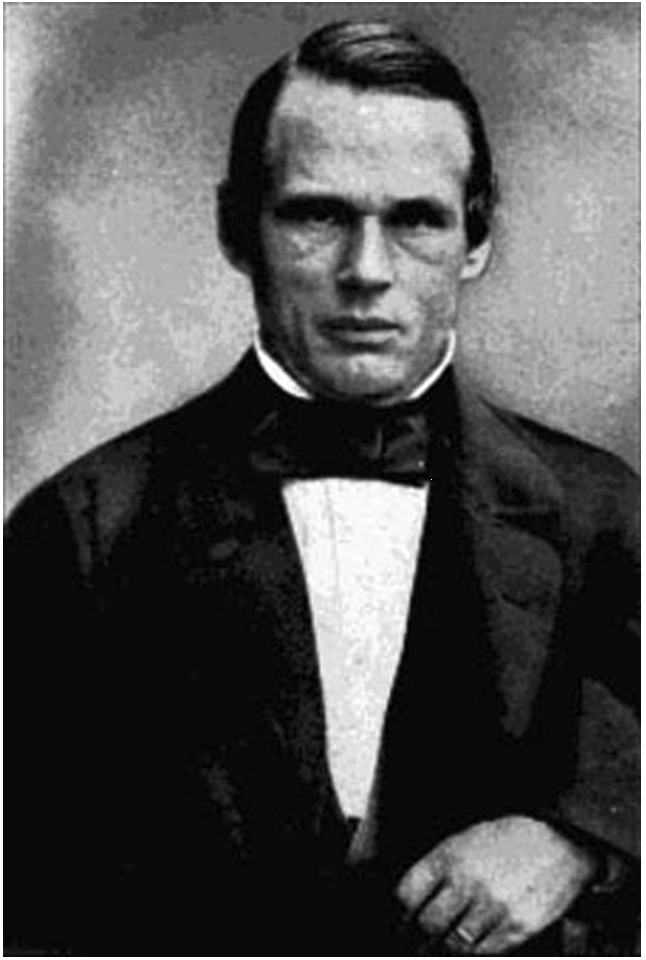

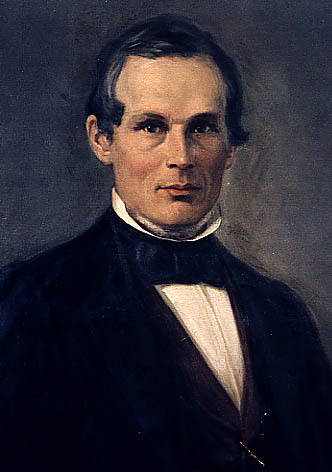

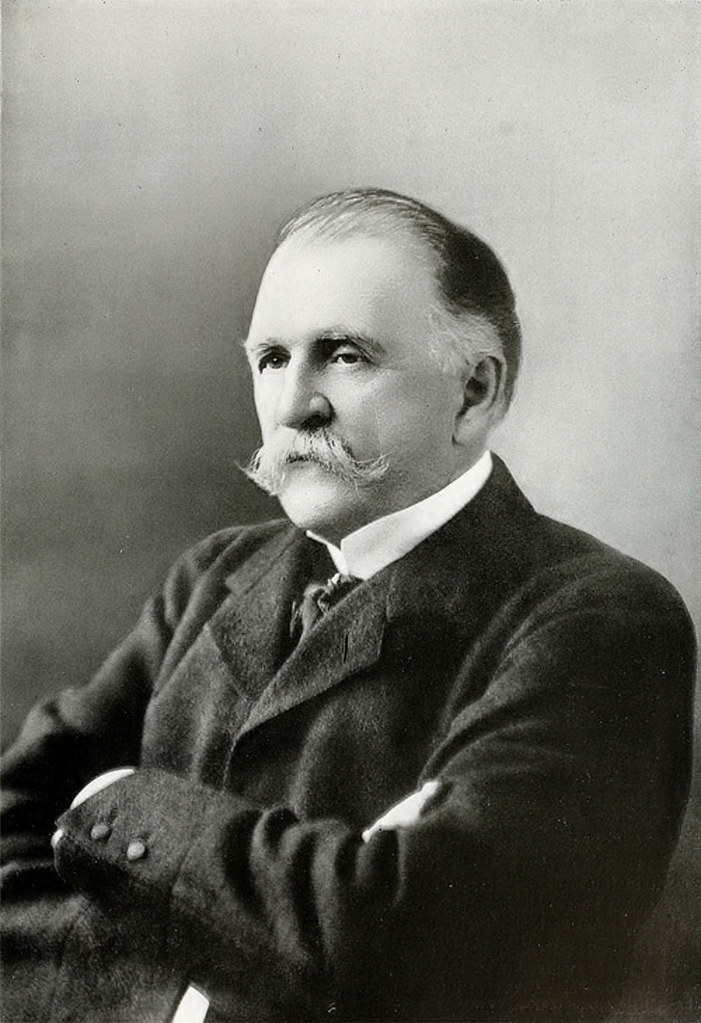

Today is the birthday of William Painter (November 20, 1838-July 15, 1906). He was born in Ireland, and in 1858 came to the U.S. “in search of better opportunities,” and settled in Baltimore, Maryland. He trained as a mechanical engineer and initially got a job “as a foreman at the Murrill & Keizer’s machine shop.” His biggest claim to fame is that he “invented the crown cork bottle cap and bottle opener. He worked with manufacturers to develop a universal neck for all glass bottles and started Crown Cork and Seal in 1892 to manufacture caps that could be used to seal the universal necks.”

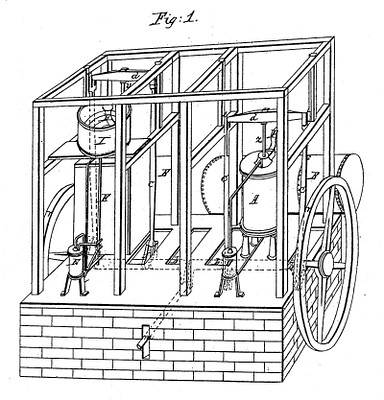

Over the course of his life, “Painter patented 85 inventions, including the common bottle cap, the bottle opener, a machine for crowning bottles, a paper-folding machine, a safety ejection seat for passenger trains, and a machine for detecting counterfeit currency. He was inducted to the National Inventors Hall of Fame in 2006.”

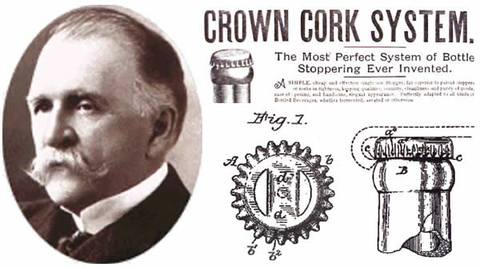

The bottle cap was arguably his most important invention. “The crown cork was patented by William Painter on February 2, 1892 (U.S. Patent 468,258). It had 24 teeth and a cork seal with a paper backing to prevent contact between the contents and the metal cap. The current version has 21 teeth. To open these bottles, a bottle opener is generally used.

The height of the crown cap was reduced and specified in the German standard DIN 6099 in the 1960s. This also defined the “twist-off” crown cap, now used in the United States, Canada, and Australia. This cap is pressed around screw threads instead of a flange, and can be removed by twisting the cap by hand, eliminating the need for an opener.”

He also patented several other innovations for the brewing industry, such as the Bottle Seal Or Stopper, from 1894, the Bottle Stopper, in 1885, a Closure For Sealing Bottles, in 1899, and a Capped-Bottle Opener, from 1894, to name just a few.