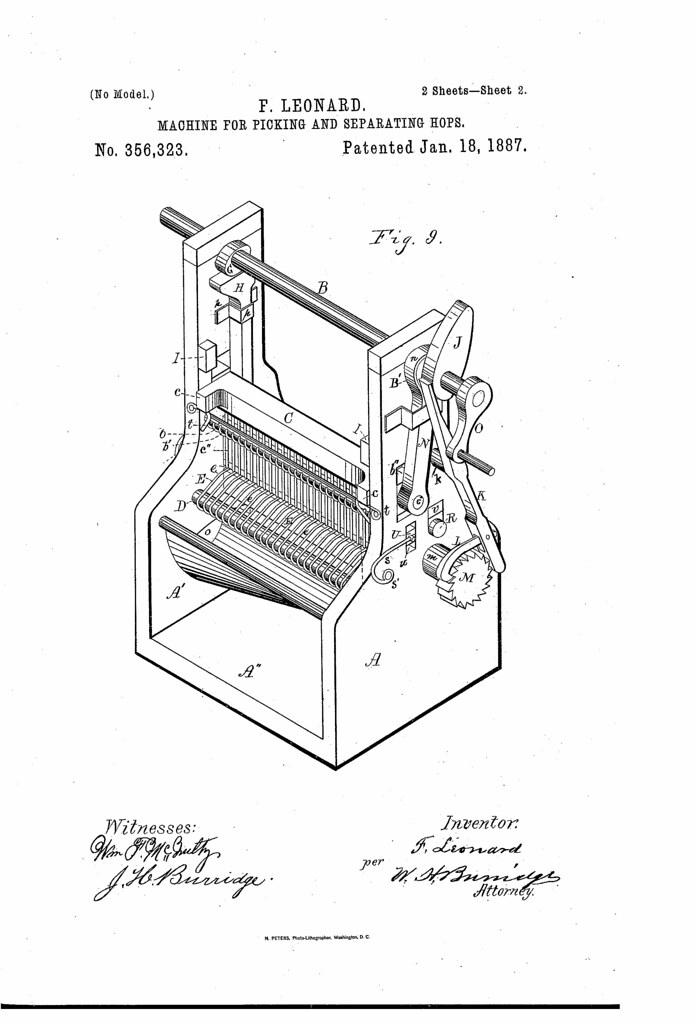

Today in 1887, US Patent 356323 A was issued, an invention of Franklin Leonard, for his “Machine for Picking and Separating Hops.” There’s no Abstract, and the description is hard to read, as well, but it’s a “new and improved Machine for Picking and Separating Hops from the Vines.”

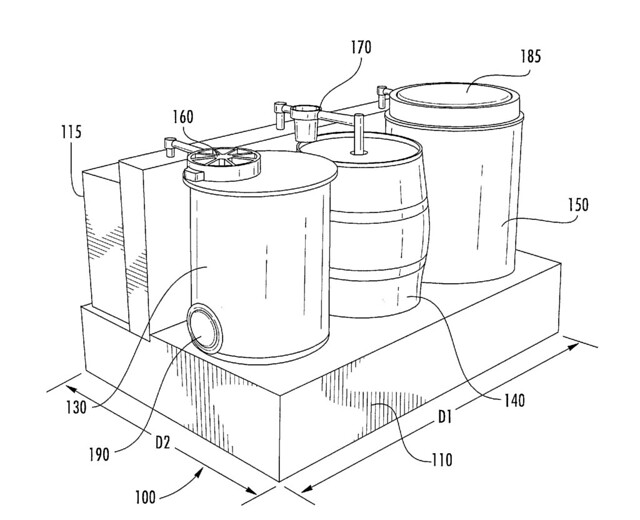

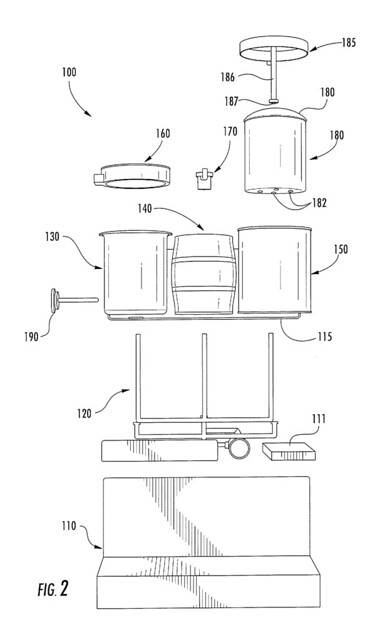

Patent No. 20140017354A1: Beer Brewing System And Method

Today in 2014, just one year ago, US Patent 20140017354 A1 was issued, an invention of James Joseph and Brandy Callanan, for their “Beer Brewing System and Method.” Here’s the Abstract:

The present subject matter relates to systems and methods for automated, whole grain brewing. In one configuration, such a system can include a base, a boil kettle positioned on the base, a first heating element in communication with the boil kettle and configured to selectively heat fluid contained in the boil kettle, and a mash tun positioned on the base, the mash tun configured to receive one or more solid or fluid materials therein. A pumping system positioned at least partially within the base can be connected to the boil kettle and the mash tun, the pumping system being operable to selectively pass fluid into, out of, and among the boil kettle and the mash tun. In addition, a control system can be positioned at least partially within the base and configured to selectively control the first heating element and the pumping system.

Essentially it’s an “automated, whole grain brewing system” for homebrewing, but you read a lot more about it in the description.

Patent No. 1328079A: Process Of Mashing

Today in 1920, US Patent 1328079 A was issued, an invention of Charles B. Davis, for his “Process of Mashing.” There’s no Abstract, and there’s not much of an introduction or overview, he just dives right into a detailed explanation of his invention. It’s curious that the patent office approved it three days before Prohibition took effect in 1920, although he first applied for the patent in 1915. Davis probably didn’t make too many sales over the subsequent thirteen years.

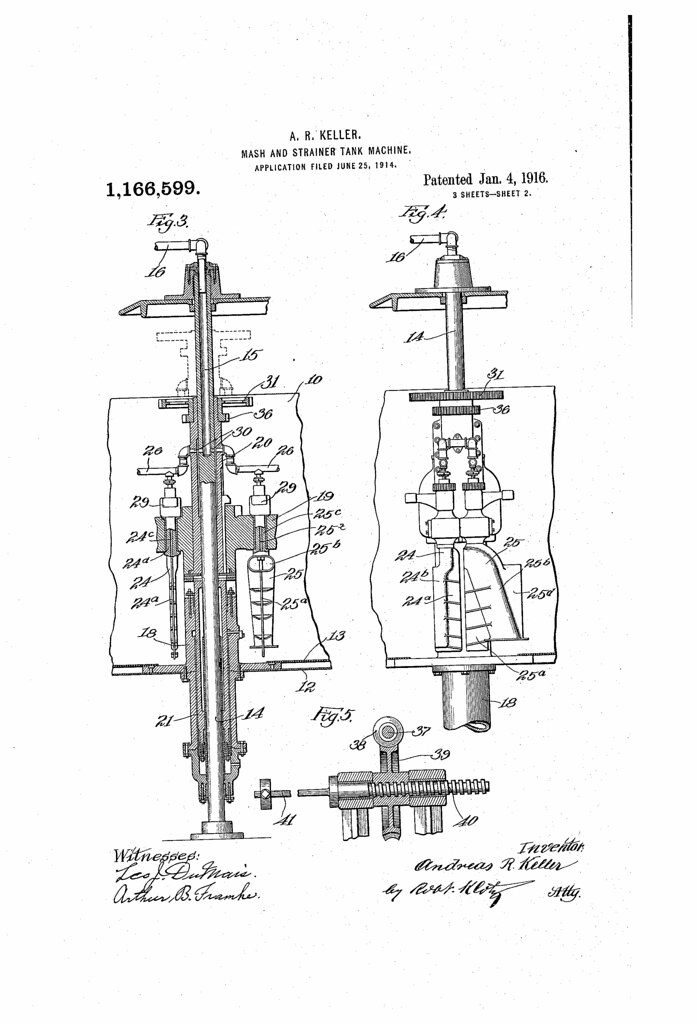

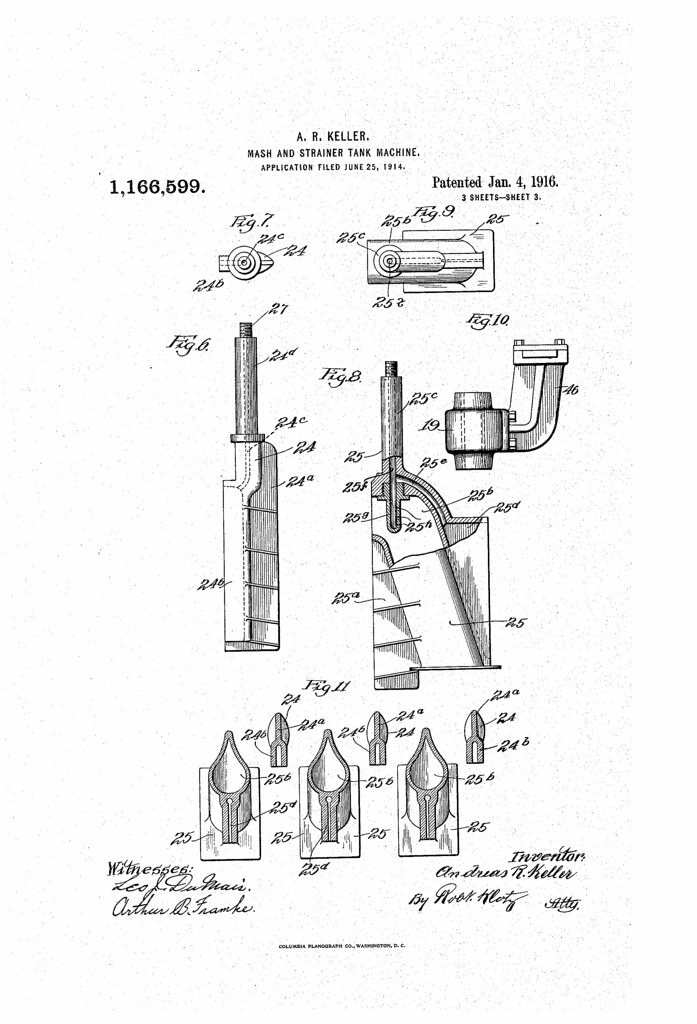

Patent No. 1166599A: Mash And Strainer Tank Machine

Today in 1916, US Patent 1166599 A was issued, an invention of Andreas R Keller, for a “Mash and Strainer Tank Machine.” There’s no Abstract, but in the description, the overview states the “invention relates to new and useful improvements in mash and .strainer tank machines, and is designed to increase the efficiency of such machines by improving the mixing, percolation, heating or cooking, straining, and drawing-off features, thereby overcoming the predominant and objectionable disadvantages of the machines now in use.”

Russian River Brewing To Get New Brewhouse

Well this is great news for Russian River beer lovers. I got the news last night that the Santa Rosa brewery will be getting some key new brewing equipment, installing a new brewhouse to replace the current one. The last brewhouse was installed in 2008, when they built their production brewery, increasing annual production from 3,000 barrels to 14,000 barrels, a 466% increase. In February of next year, they’ll be swapping out the old one to install a 4 vessel 50-barrel brew house from AAA Metal Fabrication in Oregon. So how to make beer while the new kettles are being installed? Here’s how, from the press release:

Since this is an equipment swap, there will be no way to brew at their production brewery for about a month. This will not only affect beer sales at their pub, but wholesale distribution since all packaged beer is brewed at this facility (Pliny fans should be gasping right about now). Alas, have no fear! Vinnie and Natalie’s good friends at Firestone Walker Brewing Company have graciously offered to brew several batches of Pliny the Elder to keep the beer flowing during this downtime at Russian River! Firestone Walker will brew Pliny the Elder for draft distribution only, and bottled Pliny will continue to come from Russian River through existing inventory in their fermenters. Vinnie will be working closely with Brewmaster Matt Brynildson to dial in the Pliny recipe in an effort to maintain flavor consistency. If you are at all familiar with the Firestone beers, you know their brewing practices and quality are already first class!

Vinnie and Natalie are grateful to their friends at Firestone Walker for helping them out during installation of the new brew house in February. It’s not exactly like borrowing a bag of malt! The ability to have an uninterrupted supply of draft Pliny the Elder for their wholesale partners and, especially, consumers is invaluable to them and the brewery. This is a true testament to the continued collaborative spirit and friendly nature of the Craft Beer Industry.

No word on when the swap is expected to be completed but the new shiny brewhouse will allow them to keep making great beer.

Here’s the Russian River crew in front of the old system, shortly after it was installed in 2008. As noted in the press release, Vinnie and Natalie bought it from Dogfish Head, but Sam Calagione in turn got it from Henry Ortlieb, a fourth generation brewer in the Ortlieb family, who as you can see, had it built in 1997 when he opened Poor Henry’s Brewery and Pub.

Beer In Film #91: The Self-Refilling Beer Can

Today’s beer film is a short break from featuring the Michael Jackson Beer Hunter series, which will conclude tomorrow. Because it’s April 1, our video today is one from my friend and colleague Marty Jones about Cask Brewing Systems — the Canadian company that started microcanning — and their latest innovation: the Self-Refilling Beer Can (SRBC). According to the press release, “The SRBC is a unique Cask invention that enables consumers to refill empty beer cans with the beer that was originally packaged in the SRBC.”

More from the press release:

The can has the potential to significantly change the canned craft beer segment.

“We’ve been providing innovative equipment to craft brewers since the 1980s,” says Cask president and founder Peter Love. “We’ve also been helping craft canners since 2002. But this may be the most innovative thing we’ve ever done.”

“For years,” Love says, “we’ve touted the fact that aluminum cans are infinitely recyclable. Now we can say they are infinitely refillable.”

The can was developed at Cask’s brewing research laboratory with the help of Professor Phelyx, a Denver, Colorado microcanning scientist.

“This can has incredible benefits for craft brewers,” Phelyx says. “The Self-Refilling Beer Can allows breweries to increase their beer production without

having to actually produce more beer.”To create the SRBC, Phelyx and Cask experts first created a unique resealing mechanism called the Lid Occlusion Lock (LOL) that reseals an opened can when the consumer gently rubs the can’s opening with their finger.

Once the lid is resealed, the beer drinker then lightly shakes the can to activate the In-Can Brewing System (ICBS) that then “rebrews” the original beer that was packaged in the can.

“Perfecting the ICBS was the crucial step in creating the Self-Refilling Beer Can,” Phelyx notes. “Once we were able to make that work, the Self-Refilling Beer Can went from a dream to a reality.”

In addition to providing a lifetime of craft beer to consumers, the SRBC has other benefits.

“It will quickly shrink the packaging costs for our customers,” says Cask’s Jamie Gordon, “and eliminate any waste from dented cans prior to filling. It could eliminate the need for beer can recycling, too.”

The initial response from retailers to the SRBC has not been favorable. “The lost sales alone would be devastating to my industry,” says Ron Vaughn, of Denver, Colorado’s Argonaut Wine & Liquor. “We don’t want to see it in the market.”

To address these concerns, Cask is developing a royalty system that will compensate retailers for any losses from the SRBC.

Cask officials are releasing the first samples of the SRBC to the craft brewing industry on Tuesday, April 1.

Cask officials are not divulging the price of the cans.

Cask Brewing Systems invented the beer industry’s first microcanning equipment in 2002. Cask now supplies a range of affordable, compact, high-performance canning systems to small-scale breweries and packagers worldwide.

Cask has installed over 300 canning lines in 20 countries, and is the official supplier of Ball Corporation printed aluminum cans for its Cask customers.

Marty Jones with Professor Phelyx.

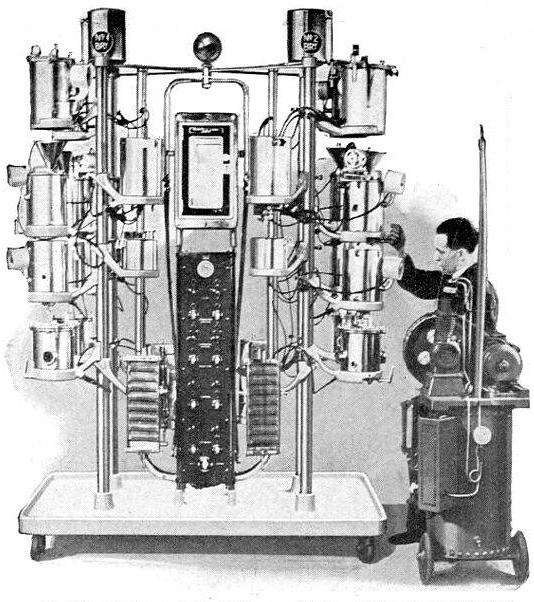

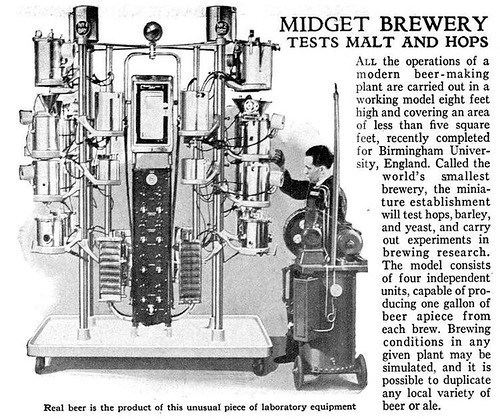

The Original Midget Brewery

Last week, Boak & Bailey tweeted about what must have been one of the earliest commercial nanobrewery systems. I tried to find out more about the Midget Brewery, though there’s scant information available on the interwebs. Here’s what I found. In 1936, page 30 of the February issue of Popular Science featured a little piece about the Midget Brewery, developed for R&D in Great Britain.

Here’s the full text that accompanied the photograph:

All the operations of a modern beer-making plant are carried out in a working model eight feet high and covering an area of less than five square feet, recently completed for Birmingham University, England. Called the world’s smallest brewery, the miniature establishment will test hops, barley, and yeast, and carry out experiments in brewing research. The model consists of four independent units, capable of producing one gallon of beer apiece from each brew. Brewing conditions in any given plant may be simulated, and it is possible to duplicate any local variety of beer or ale.

How Ales & Lagers Are Fermented

The Process of Brewing Beer

![]()

Today’s infographic shows the stages of the brewing process graphically. It’s called simply The Process of Brewing Beer.

Damaged Lagunitas Equipment In Petaluma

When last we looked, the damaged Lagunitas brewing equipment was at the dock, at the Port of Stockton. Earlier today I stopped by the Lagunitas Brewery to pick up some samples for a tasting tomorrow for the Celebrator Beer News and, not surprisingly, the broken lauter tun was around the back of the brewery. Having traveled so far — the equipment, not me — I wanted to see it close up and snapped some photos, too.

At the Lagunitas Brewery.

The damaged brewhouse in Petaluma.

Some of the damage, up close and personal.

Close-up mayhem.